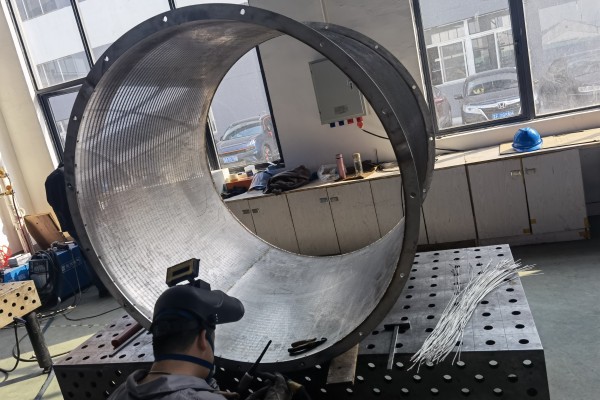

Last few months, our factory produced a batch of stainless steel wedge wire screen cylinders, which will be used in sugarcane juice processing and production.

These wedge wire screen cylinders perform exceptionally well and are widely applied in the food and beverage processing industry.

This is primarily due to their excellent filtration efficiency, high flow rate, V-shaped slots that resist clogging, and effective backwashing and self-cleaning capabilities.

They also offer strong corrosion resistance, long service life, and significantly improve production efficiency and capacity.

Below are the advantages and features of stainless steel wedge wire screen cylinders used in sugarcane juice processing:

1. Core Technical Advantages

V-Shaped Slot Design

The wedge wires are arranged in a trapezoidal pattern, forming slots that are wider at the top and narrower at the bottom. This design effectively traps solid impurities (such as sugarcane fibers and sediment) while allowing high flow rates.

Under high-pressure washing, this structure quickly releases trapped particles, outperforming traditional mesh screens.

Corrosion Resistance & Hygiene

Made from 316L stainless steel (or custom materials), they resist the acidity of sugarcane juice (containing citric acid and oxalic acid) as well as high-temperature, high-humidity environments.

Compliant with FDA/EC food-grade standards, ensuring no metal ion contamination.

Self-Cleaning Capability

Combined with a back-flushing system or ultrasonic cleaning technology, the "self-discharging" feature of the V-shaped slots reduces downtime for maintenance, making them ideal for continuous production (e.g., 24-hour pressing lines).

2. Key Applications in Sugarcane Processing

Primary Juice Filtration

Replacing traditional filter cloths, wedge wire screen cylinders are installed directly after the press to separate juice from bagasse, improving the purity of raw juice (reducing the load on subsequent clarification steps).

Juice Fine Filtration

The wedge wire screen durm is used alongside centrifuges or membrane systems, they remove micron-level suspended solids (e.g., colloids, fine fibers), extending the lifespan of evaporators and crystallization equipment.

Bagasse Recovery

The filtered bagasse filtered through the wedge wire screen drum has a lower moisture content, making it easier to repurpose (e.g., as fuel or feed), thereby increasing economic benefits.