The V wire screen lateral distributor has inherent even pattern, which is made of stainless steel, hastelloy alloy steel and other alloy steels. it has various slot size, wire size and diameters to suit common or customized applications.

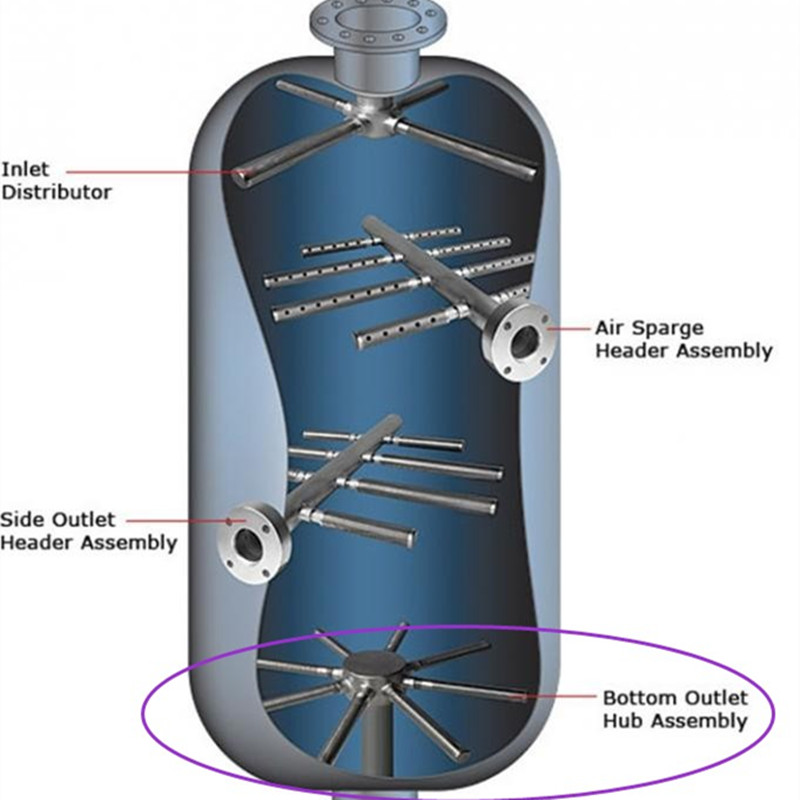

Stainless Steel Hub And Header Laterals promote even distribution while also avoiding flow/pressure concentrations. Each header lateral consists of a series of screen laterals connected to a central header to provide uniform flow within a vessel containing treatment media.

The header pipe features flange connections at both ends for easy installation and disassembly when integrating into the system.

The lateral pipes on both sides adopt a dual-layer structure, consisting of an inner liner pipe and an outer filter screen pipe.

The inner liner pipe is perforated, with hole size and quantity precisely designed based on flow requirements.

The outer filter pipe is stainless steel wedge wire screen, with slot sizes typically ranging from 0.1–0.5mm, optimized for flow performance.

Both the header pipe and inner liner pipe are constructed from seamless pipe, which provides higher roundness, greater strength,

and better durability compared to conventional welded pipes.

The laterals' wedge wire screen is manufactured by V-shaped stainless steel wires, precision-welded on specialized winding equipment.

We all know the advantage of wedge wire screen:

Uniform slot openings for consistent flow distribution.

High filtration accuracy with minimal clogging.

Easy backwashing and self-cleaning capability.

Excellent pressure and impact resistance.

High flow capacity for efficient operation.