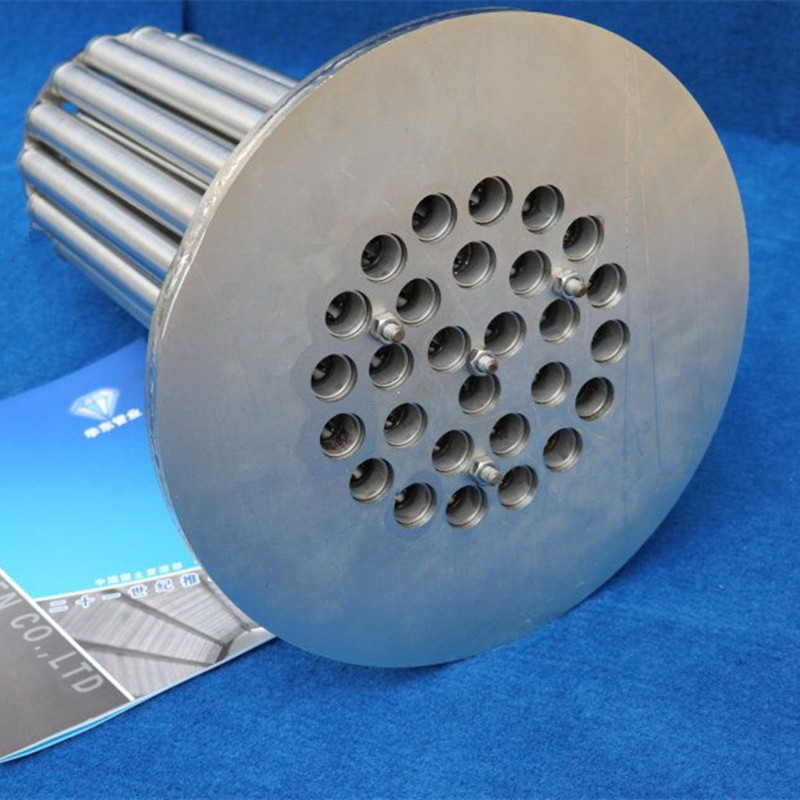

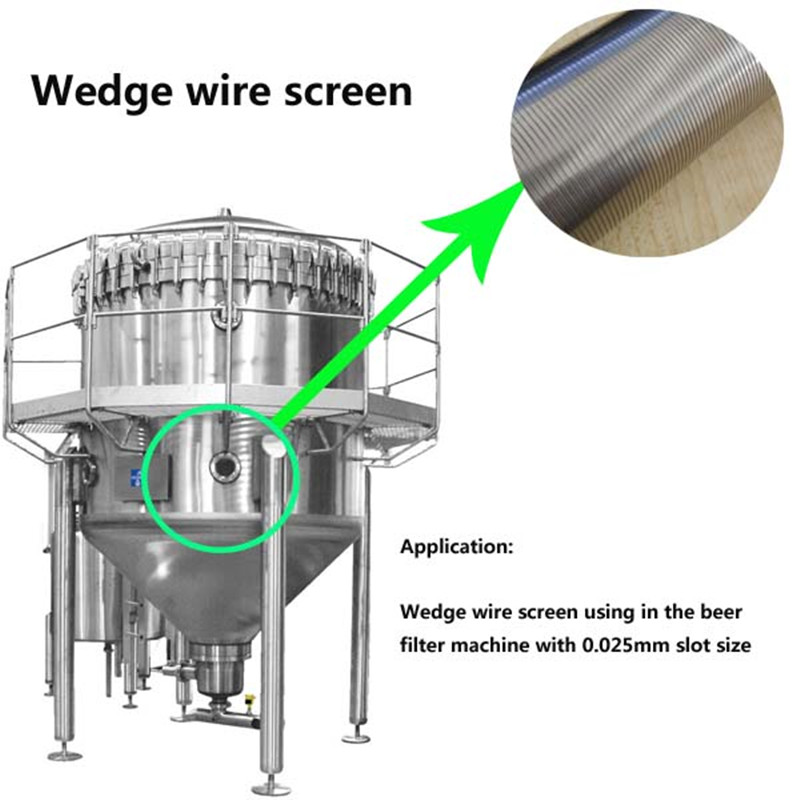

The candle filter element is the most important component of the reverse flushing equipment. Its V-shaped gap enable the equipment to have the function of reverse flushing.

Here are the roles of the reverse flushing equipment in beer processing:

Removing blockages in the filter layer: Removing impurities such as yeast, proteins, and hop residues that are trapped on the surface of the filter medium (such as diatomaceous,membranes).

Restoring filtration capacity: Preventing a decrease in flow rate due to an increase in pressure difference, ensuring the clarity and stability of the beer.

Automated cleaning: Reducing the frequency of manual disassembly and cleaning, significantly improving production efficiency.